Mechanical Engineering - Production Engineering

Exercise : Production Engineering - Section 7

16.

For turning small taper on long workpiece, the suitable method is

17.

In a milling operation, two side milling cutters are mounted with a desired distance between them so that both sides of a workpiece can be milled simultaneously. This set up is called

18.

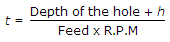

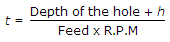

The time (in minutes) for a drilling a hole is given by

where h is the

where h is the

19.

Crack in grinding wheel is developed due to

20.

The average cutting speed for turning mild steel with a high speed steel tool is

Quick links

Quantitative Aptitude

Verbal (English)

Reasoning

Programming

Interview

Placement Papers